Three Ways to Improve Efficiency of Student Housing Turnover

Delivering a project on time is the goal for any construction project, but in student housing, it is critical! With Juneau’s extensive experience in delivering more than 22,000 beds, we have identified key strategies to improve the efficiency of the most crucial phase in student housing construction – final turnover. Here’s how we ensure timely project delivery despite today’s market challenges:

CLEAR, FREQUENT AND OPEN COMMUNICATION

To keep the project on schedule, it’s essential that every project stakeholder clearly understands their roles and responsibilities from day one. Establishing open lines of communication among all OAC (Owner, Architect, Contractor) members early on helps with quick decision-making on time sensitive items that could impact the schedule. In today’s climate of unpredictable material lead times and pricing volatility, failing to make timely decisions can lead to unexpected price escalations, budget overruns, schedule delays or resequencing. It is our job to have an acute awareness of the current market conditions and provide a comprehensive procurement schedule to clearly identify critical approval and release deadlines. Early OAC buy-in and strict adherence to the procurement schedule are paramount to maintaining control of the GMP.

While not all allowances and scope uncertainties can be resolved before the GMP is set, it is important to collectively agree during the preconstruction phase, to proceed with the goal of reducing allowances and undefined scope as much as possible. This can tremendously reduce the risk of unforeseen escalations later in the project and allow for more competitive pricing during the GMP bidding process. Once construction is underway, it is essential that all OAC team members are in constant communication regarding material procurement challenges and supply chain issues in today’s market. These must be communicated immediately when challenges arise to quickly identify alternative options with input from the OAC team and trade partners. To keep construction moving, it is important to get these alternative options approved quickly. If resequencing work is required to accommodate these changes, it is key to ensure all trade partners contribute and buy in to the new plan.

SYSTEMS COORDINATION

Effective systems coordination, particularly for life safety systems, is crucial to the phased unit turnover and early FFE (Furniture, Fixtures, and Equipment) move-ins in student housing projects. Our teams work closely with municipalities from the outset to understand all inspection requirements and communicate these back to the OAC team to ensure the program supports a strong finish. We ensure these inspections are scheduled and completed in an expedient fashion to push the schedule forward and take advantage of early and phased FFE move-ins whenever municipalities allow it.

We utilize BIM to develop a fully populated coordination model during preconstruction and throughout the project. Constructing the building in a digital space first allows our team to verify design intent against MEP systems and other critical features that may not be fully developed within the drawings, identifying and resolving major conflicts early. This proactive approach reduces costs and inefficiencies in the field, helping us avoid schedule disruptions due to coordination issues.

EFFICIENT UNIT TURNOVERS

Successful turnover of a large volume of units requires establishing quality control (QC) standards with all trade partners before ever stepping foot on the jobsite. This ensures that everyone is aligned with the project-specific QC plan and schedule, leading to quality work completed on time. As construction progresses, the Juneau team employs a “punch as we go” strategy, conducting up-to-date QC audits and observations. This approach allows for timely adjustments and corrections, preventing the accumulation of punch list items that could delay the project. These requirements are regularly communicated to trade partners during Pre-Install Meetings, Daily Morning Huddles, Near-Term scheduling, and more so that everyone is working towards the same goal.

Once the scopes are complete in a defined area, the Juneau team completes its punch list prior to the owner beginning their own punch process to help with efficiency of unit turnover. A phased punch process allows for early next steps in units or common areas to capitalize on any time gained.

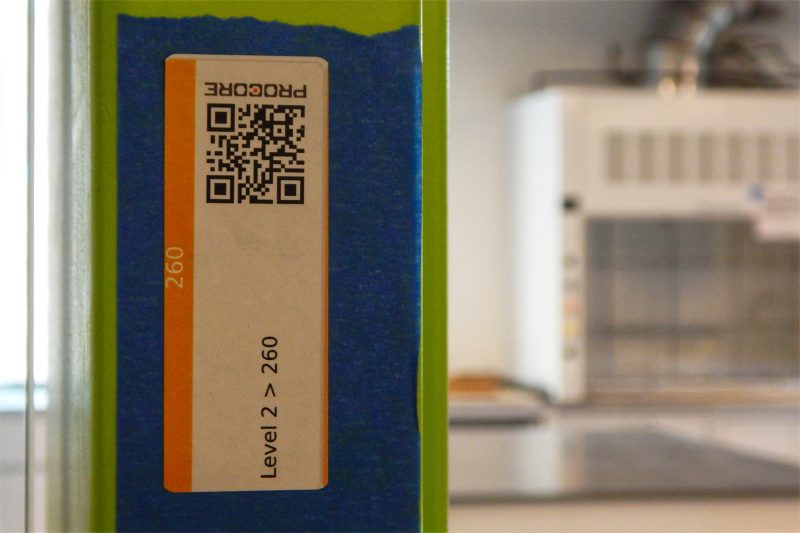

The use of technology improves the efficiency and organization of the punch process which is crucial in multi-unit construction. By assigning QR codes to individual units, the Juneau team can easily track and confirm punch-list progress through Procore since all trade partners are updating the master punch list in real time. This information is regularly shared with the Owner teams to help them manage their FFE installation schedule, ensuring a seamless transition.

Assigning a Procore QR code to each individual unit allows the Juneau team to easily track the punch-list progress.

Minimizing issues during construction through meticulous planning and coordination is vital to prevent schedule erosion and ensure on-time turnover. By establishing clear communication from day one, coordinating building systems before construction begins, and adhering to strict QC standards throughout the project, Juneau consistently delivers student housing projects on time, meeting the high expectations of our clients.

Back to All Insights