Top 5 Construction Safety Lessons Learned

1. Take the time to ask questions

“When an incident occurs on a jobsite it’s easy to jump to conclusions and assume you know what caused that incident. It is important to remember that everyone on a construction site knows something about that job that you don’t know. If we take the time to be intentional and ask questions, we can better understand the jobsite we are on and fully understand the situation at play. By doing that, we can then figure out how to build systems and solutions that makes the jobsite safer.”

– Blake Jones, Corporate Safety Director

2. Ensuring all employees on a jobsite are trained for that job

“Construction is a unique industry with hazards that may not be so apparent for people that are unfamiliar with that environment. For that reason, every employee that steps foot on a Juneau project must participate in a jobsite safety orientation, periodic safety awareness, and specialized trainings. Not all of these are done by the General Contractor, but all training is verified prior to employees starting work. We must make sure we are providing people with the tools, and a system to make them successful.”

– Blake Jones, Corporate Safety Director

3. Requiring written, task-specific plans to ensure safety

“Because a majority of our current work is comprised of wood frame structures, which can have a significant impact on safety and quality, we require all of our wood framing subcontractors to create and submit a site-specific safety plan, task-specific plans, and a job hazard analysis. For example, when the balcony on a third story apartment building has the guardrails removed to receive materials, how will the employees be protected that are on the balcony? Requiring written plans dramatically reduces the probability of incidents occurring.”

– Blake Jones, Corporate Safety Director

4. Enforcing qualified NCCCO operators, lift plans, and inspections for cranes

“When I think of a construction site, images of tower cranes hovering over a city skyline come to mind. This play a major role in how work gets done and is something to get excited about. However, as history shows, cranes can be one of the largest hazards to manage on a project. Having qualified NCCCO certified operators, lift plans, and 3rd party inspections for cranes are all controls we have put in place to mitigate that hazard and ensure safety on projects where tower cranes are present.”

– Blake Jones, Corporate Safety Director

5. Having patience

“I as a frequent visitor to all of our jobsites, I have noticed that you must be patient when explaining safety practices to employees and subcontractors. Following a conventional approach doesn’t always work. Many workers have been in their trade for years and believe their method works. However, just because it has worked for them for years, doesn’t mean it is the safest approach. You must keep an open mind and be patient when explaining a safety procedure and why it must be followed. Even if it means removing a subcontractor from a jobsite for them to realize the importance of following a specific procedure, it is worth them understanding OSHA and Juneau standards. It may take multiple times to explain and demonstrate why, however it will make an impact and make the worker safer.”

– Carlos Collado, Safety Manager

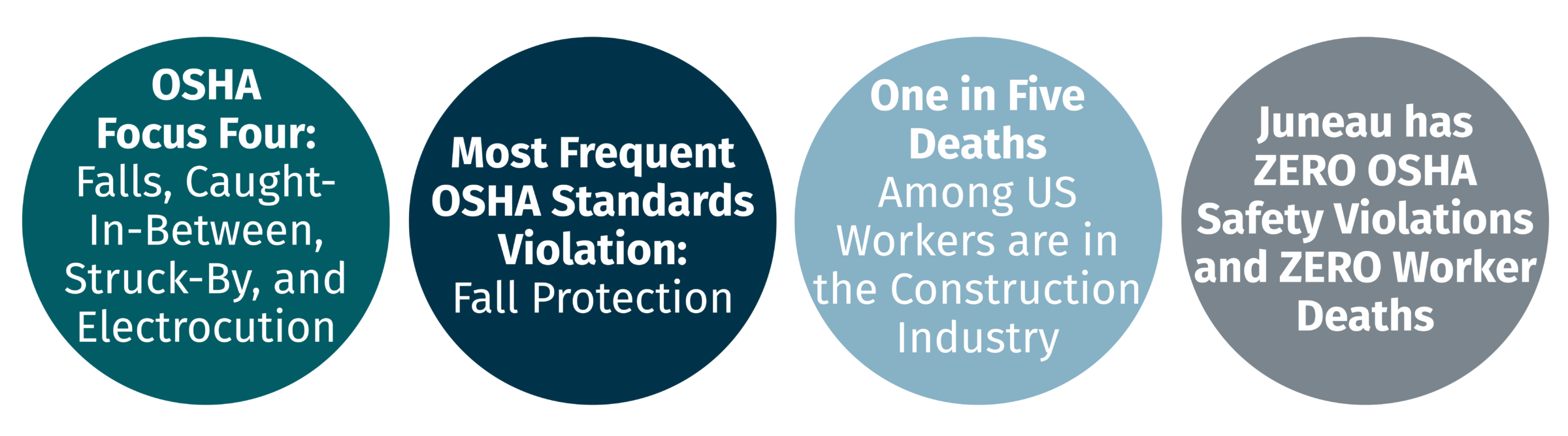

*Statistics provided by www.osha.gov

Back to All Insights